One of the most useful skills when performing DIY electronic repairs around the house is the ability to solder. A medium-temperature lead-free soldering procedure is used for welding the fins to an aluminum or copper foundation in a soldering heat sink for environmental preservation. The process of soldering, pronounced “sold-er-ing,” is effective for connecting electrical parts and cables.

In order to create a tidy, effective electrical connection, solder is added as a filler material to a joint. Extremely high temperatures can be extremely harmful to electronics, causing parts to burn, act erratically, or have a shorter lifespan. Overheating is a problem even though soldering is a low-temperature process, especially for small components.

Such connections can be made at low temperatures using soldering. Soldering only needs to reach temperatures of 200–300°C to create strong connections, as opposed to welding or brazing, which melt and practically fuse metals together at temperatures of 600 °C or higher soldering heat sink has most of the electrical applications.

Working Of Soldered Heat Sinks

- The heat sink is a device that engineers created over time to address the issue of overheating when soldering.

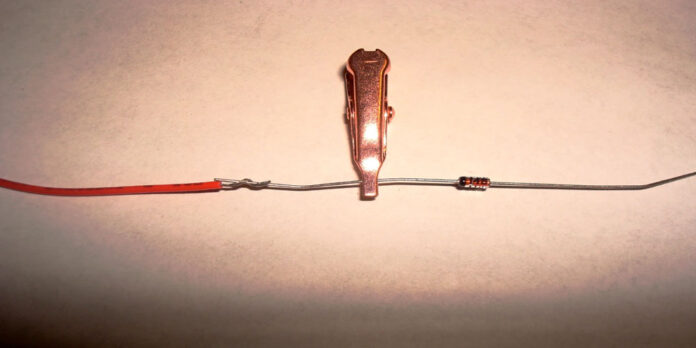

- The soldering junction and the heat-sensitive component are separated by special heat sink tools, which resemble little clamps.

- Engineers came up with a tool throughout time to deal with the issue of soldering overheating: the heat sink.

- Placed between the soldering joint and the heat-sensitive component, dedicated heat sink tools resemble little clamps.

- Alligator clamps can be used to create temporary heat sinks.

- There are normally two types of heat sinks sold by professionals: those with curved ends and those with straight ends.

- They may be more adaptable for small joints and leads if they have bent ends. If not, the majority of electricians advise using heat sinks with straight edges.

Types of Soldered Heat Sinks According To Temperature

High-temperature soldering and low-temperature soldering are two categories for soldering heat sinks.

High-Temperature Soldering

The heat sink needs to be welded at 700–800 degrees for high-temperature soldering.

Low-Temperature Soldering

This soldering uses a heat sink temperature between 200 and 300 degrees and is a commonly used soldering technique. It essentially results in no deformation, can be processed with great precision, and may be utilized with any equipment.

Soldering Tools

Some of the vital tools, like the solder, are important, while others are considered optional. (But thought out as recommended).

Soldering Iron

There is an important consideration of the usage of a soldering iron. Let’s overlook the MacGuyver fans who have attempted to solder with a regular cigarette lighter for the time being. You should get an iron if you wish to solder with any degree of precision. There are many different sizes and shapes of soldering irons.

Rosin Flux Core Solder

You may come across some types of solder that contain what are known as “rosin cores” or “rosin flux.” The materials that you put the solder on will be cleaned by this acidic substance. I advise using solder with rosin cores for soldering electronics. It ought to be simple to locate.

Solder

Tin and lead are traditionally alloyed in a 60/40 ratio to create traditional solder. It has an incredibly wide range of applications for creating low-temperature connections for items like cables and circuit boards because of its melting temperature of about 200 °C. The metals used to make solder make it extremely electrically and thermally conductive.

Last Wording

Heat sinks may be essential for successful soldering. They can save your components and lengthen their lives, and they’ll stop your wire insulation from catching fire or closing before you want it to. You will place a heat sink between the soldering joint and the component to use one. (Or insulation). Any surplus heat will be directed away by the heat sink, ensuring optimal operation of the component and insulation.